Green hydrogen production is electricity-intensive, and the production costs depend strongly on electricity costs. However, our electrolysers are operated to serve the grid and are thus exempt (in Germany, at least) from grid charges and electricity tax. This significantly improves the competitiveness of our hydrogen solution compared to direct electrification.

Also think about:

Anyone who wants to convert to hydrogen today needs five different partners:

This is expensive and requires a lot of planning. That’s why NextHeat offers H2 burner and electrolyser modules that are matched to each other precisely, minimising the effort required to integrate them during the switch. From as little as 100 kW gas demand, you can gradually convert your production to hydrogen and prepare your processes for the climate-neutral energy carrier.

And the best part? After an initial analysis of your heat requirements and existing production facilities, we will guide you through the entire implementation process so that you save time and money. This means you can actually concentrate on your core business.

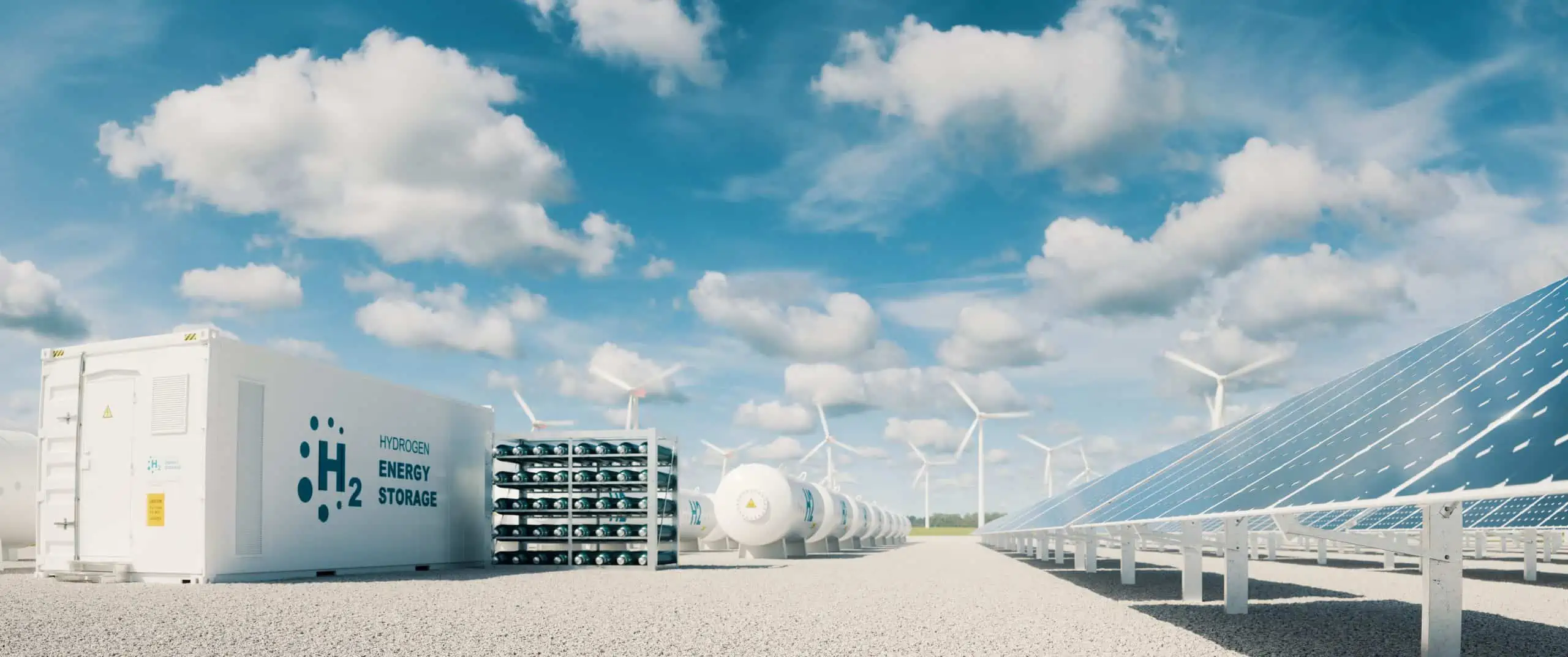

What’s more: NextHeat electrolysers are also equipped with an intelligent control solution that allows them to be connected to a renewable energy plant, thus ensuring low electricity costs and certified green hydrogen.

Contact us.